Pharmaceutical Automated Storage Revolutionizes Warehousing in Botswana

Have you ever wondered how pharmaceutical companies manage their vast inventory efficiently? Well, the answer lies in the innovative technology of pharmaceutical automated storage. Let’s explore how this cutting-edge system is transforming the warehousing industry in Botswana.

The Game-Changing Solution: HWArobotics and Pharmaceutical Automated Storage

In a remarkable project by Sichuan Kelun Medicine & Trade Group, a state-of-the-art pharmaceutical automated storage system has been implemented at their logistics center located in Xindu District, Chengdu. With an impressive investment of over USD 13.8 million, this facility covers an area of approximately 100,000 square meters.

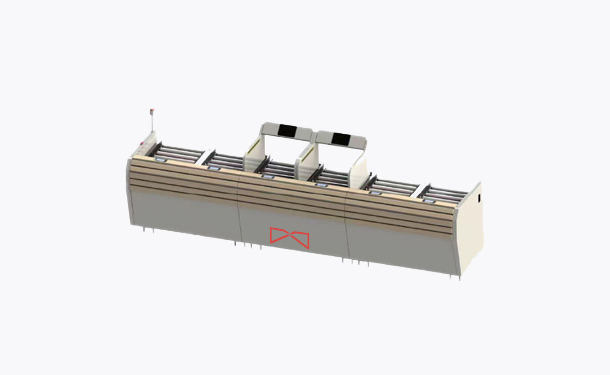

To tackle the complex process of split picking in pharma warehousing, Sichuan Kelun Medicine & Trade has partnered with HWArobotics to deploy a multi-level AS/RS shuttle system. This advanced solution utilizes 78 SLS320 standard case-handling shuttles operating within a six-aisle AS/RS that accommodates more than 33,000 storage units.

A New Era for Pharma Warehousing Efficiency

This implementation marks a significant milestone for pharmaceutical automated storage systems as it revolutionizes traditional warehousing practices. The adoption of such technology enables seamless management of inbound and outbound flows while ensuring optimal space utilization within the warehouse.

Gone are the days when manual handling and sorting were time-consuming tasks prone to errors. With pharmaceutical automated storage systems like those developed by HWArobotics, efficiency is maximized through precise automation and intelligent algorithms that streamline operations from start to finish.

Enhanced Safety Measures and Inventory Control

One crucial aspect addressed by these advanced systems is safety measures for storing sensitive medications properly. Pharmaceutical automated storage systems provide a controlled environment that minimizes the risk of contamination and ensures compliance with strict regulatory standards.

Moreover, inventory control becomes significantly more efficient with real-time tracking and monitoring capabilities. The system accurately records every movement within the warehouse, allowing for precise stock management and reducing the likelihood of errors or discrepancies in inventory levels.

The Future of Pharma Warehousing

As technology continues to advance at an unprecedented pace, pharmaceutical automated storage systems are poised to become even more sophisticated. With ongoing research and development efforts, we can expect further enhancements in areas such as artificial intelligence integration, predictive analytics, and robotics.

This evolution will undoubtedly lead to increased efficiency, reduced costs, and improved patient safety within the pharmaceutical supply chain. As Botswana embraces these advancements in warehousing technology, it positions itself as a frontrunner in Africa’s pharmaceutical industry.

In conclusion,

Pharmaceutical Automated Storage: Revolutionizing Warehousing Efficiency

The implementation of pharmaceutical automated storage systems powered by HWArobotics has brought about a paradigm shift in how pharma warehouses operate. By leveraging cutting-edge technology like AS/RS shuttle systems, companies can optimize their operations while ensuring product integrity and regulatory compliance. As Botswana embraces this transformative solution for its logistics needs, it sets an example for other nations seeking to enhance their healthcare infrastructure through innovative automation.